What do you all think?

#1

What do you all think?

Well at first I was going to machine a spool for my Rv200 diff, but after thinking it over, and speaking with my teacher, we figured it might be easier to make a mini spool. I figured if I made a mini spool to fit inside the carrier and replace the Vicious set up, it would be fully locked. Has anyone attempted it? I know a couple people that have made a full spool but not a mini for the 240.

I would make the full spool, but our EDM machine won't go tall enough so I can do the splines.

Anyone recommend me some idea's they might have came across? or a type of metal that would work the best? I plan to machine it out of aluminum.

I would make the full spool, but our EDM machine won't go tall enough so I can do the splines.

Anyone recommend me some idea's they might have came across? or a type of metal that would work the best? I plan to machine it out of aluminum.

#3

The only thing I don't like is on the VLSD it's basically 4 points that connects the carrier and axle shafts together. I got the diff pulled now and I will take some pictures to show more of what I mean.

#4

I started doing some measuring and planning today.

I am still debating on either a full spool, or mini spool.

After looking it over there is 3 different ways I can go about the mini spool, I just have to figure out which one if I do go that route.

First one is to machine it all in one shot.

Second is machine the cylinder with splines all in one shot and add dowl pins to lock the axle shafts to the carrier.

Third is to do it in 3 pieces and when it's all put together it would be fully locked.

I just have to do some thinking as to which would work the best since all 3 are good options.

I also figured I will be making it out of 4140 steel.

I am still debating on either a full spool, or mini spool.

After looking it over there is 3 different ways I can go about the mini spool, I just have to figure out which one if I do go that route.

First one is to machine it all in one shot.

Second is machine the cylinder with splines all in one shot and add dowl pins to lock the axle shafts to the carrier.

Third is to do it in 3 pieces and when it's all put together it would be fully locked.

I just have to do some thinking as to which would work the best since all 3 are good options.

I also figured I will be making it out of 4140 steel.

#5

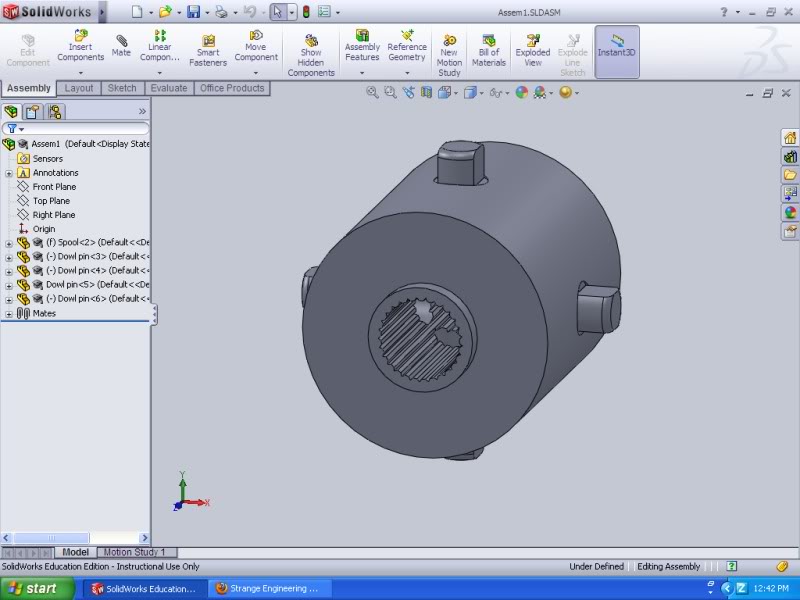

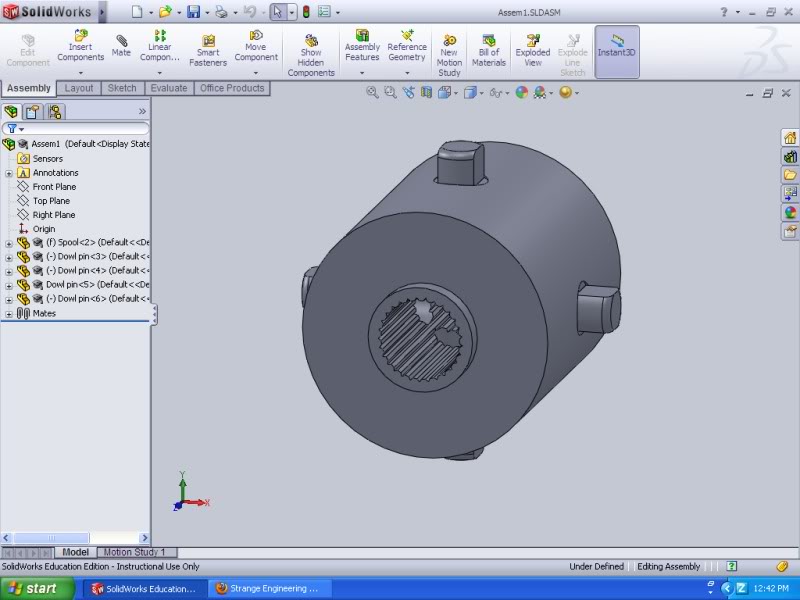

Did some work on solidworks today and this is what the mini spool is going to look like. I will be adding in some chamfers so there isn't any sharp edges. I was going to go with 4140 tool steel but taking it from a 12"x12" square to 3.5 diameter was going to be a pain. So I am going to try some Hot rolled steel for now.

#7

Yeah it is, it get's really addicting haha. I am going to school for machine tool technology and they require you take a 3D modeling class. I hated it at first, but when I got the hang of the software I will just sit down and model random things haha.

#9

I had this same conversation earlier haha. Well to weld the VLSD would be hard to do compared to just an open. And I cannot afford a 2way. It's not honestly too much work for me, I am going to school for it and in the end this will just help my ability's even more. Since I am doing this in school I won't have to pay for it(unless I use 4140 steel since it's expensive).

#11

Really? It just seems like a lot of work to keep it together. I ordered shims since one of them was burnt up. It took 5 months. I ordered 4 so I could replace them and add 2, and they only ordered me 2. I wasn't going to wait 5 months for 2 more.

#12

hhaha wow that long for shims... When I did mine I screwed it up because I didn't shim both sides of the diff. Other guys I was with did it and you would swear it was a 1.5way.

http://240sxdrifter.tripod.com/writeups/vlsdshim.html

http://240sxdrifter.tripod.com/writeups/vlsdshim.html

#13

hhaha wow that long for shims... When I did mine I screwed it up because I didn't shim both sides of the diff. Other guys I was with did it and you would swear it was a 1.5way.

http://240sxdrifter.tripod.com/writeups/vlsdshim.html

http://240sxdrifter.tripod.com/writeups/vlsdshim.html

With the stock shims there is so much play in there.

I got one side completely done and just have about .080 left on the inside hole. I will have pictures tomorrow after I get it completed.

#15

Good thing I have no idea what you guys are talking about. I guess it's guys like me that ensure the differential business stays intact. Rofl; however, I am looking forward to seeing pictures and hearing about how it all works.