Where to buy a FULL pulley kit

#31

#32

#33

as far as i know there is only one company that makes dampening pullies for the KA and its ATi and they arnt cheap $500-$1500 forgot how much exactly.

i just run the stock crank pully with everything else changed but nothing is underdrive and i have no belt slap because i use the stock crank pully.

imo i didnt feel a huge difference at all i mean by itself its not much but with other mods it adds up. i got my light weight flywheel after and that was a HUGE difference.

i say just leave the crank pully alone just replace the rest

i just run the stock crank pully with everything else changed but nothing is underdrive and i have no belt slap because i use the stock crank pully.

imo i didnt feel a huge difference at all i mean by itself its not much but with other mods it adds up. i got my light weight flywheel after and that was a HUGE difference.

i say just leave the crank pully alone just replace the rest

#34

you're forgetting something adam, you have a sr so obviously it would respond better than a ka. if fact i don't believe i've ever seen a dyno of any na application. even then it was like 8hp with all the pulleys at around 7500rpms. don't quote me on that last part because it's been a while since i've bothered looking into. either way let us know how it goes.

#35

Thats a dyno ImportTuner did back when Unorthodox was still making the KA Pulley Sets, this was done on an 96' S14

Peak numbers were:

130whp -> 138whp

142wtrq -> 150wtrq

Still not worth the engine damage in the end from the Crank Pulley, just run the Underdrive set and be done w/ it...

#36

Thats a dyno ImportTuner did back when Unorthodox was still making the KA Pulley Sets, this was done on an 96' S14

Peak numbers were:

130whp -> 138whp

142wtrq -> 150wtrq

Still not worth the engine damage in the end from the Crank Pulley, just run the Underdrive set and be done w/ it...

#37

but why why why why go underdrive? just go lightweight. with underdrive the actual pully is smaller so like vinny said your powersteering will be weaker AND your alternator wont be charging properly at idle.

just buy a light weight pullies not underdrive

just buy a light weight pullies not underdrive

#38

The devil also plays on the ignorance of people. So if you chose to think that an under drive crank pulley is the way to go, don't go crying to s-chassis.com when you wonder why your cylinder compression is low, and your engine spun a bearing as well after 6 months.

#39

And I highly doubt you'll see gains w/ LW pulley's considering pulleys are light to begin w/ IMO

#41

Just machine the stock pulleys. Extrude and remove metal, but make sure to keep it balanced. I'm actually looking to find a way to drill holes in the stock pulleys to make them lighter.

#42

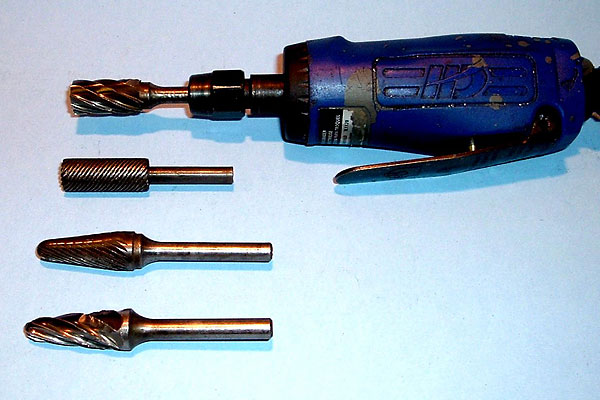

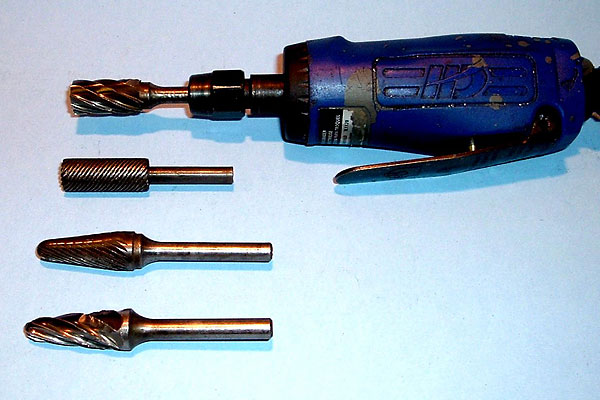

there shouldn't be a problem with balancing them since the diameter is so small. also if you take a look at the p/s pulley in my sig you'll notice that the holes are considerably larger. i didn't do it to reduce weight but rather so it would look different. all it takes is a drill press and a carbide bit like these.

#43

hmm, an interesting idea, i do have a drill press and could pick up a carbide bit, but how do i check if the pulley is still balanced after i drill it?

#44

Best thing you can do to keep it close to balanced is to measure the diameter of the pulley. Find a mathematical equation to partition the pulley into sections and remove the metal according to the pattern or arrangement that you would remove the metal. Make a couple of template moch ups and see what you can come up with. Like Jramos said, you shouldn't be to concerned with balancing since the rotating mass is so small.

Last edited by BigVinnie; 04-22-2009 at 09:49 PM.

#45

Best thing you can do to keep it close to balanced is to measure the diameter of the pulley. Find a mathematical equation to partition the pulley into sections and remove the metal according to the pattern or arrangement that you would remove the metal. Make a couple of template moch ups and see what you can come up with. Like Jramos said, you shouldn't be to concerned with balancing since the rotating mass is so small.

would this be safe to do with the crank pulley also? or just the accessory pulleys?